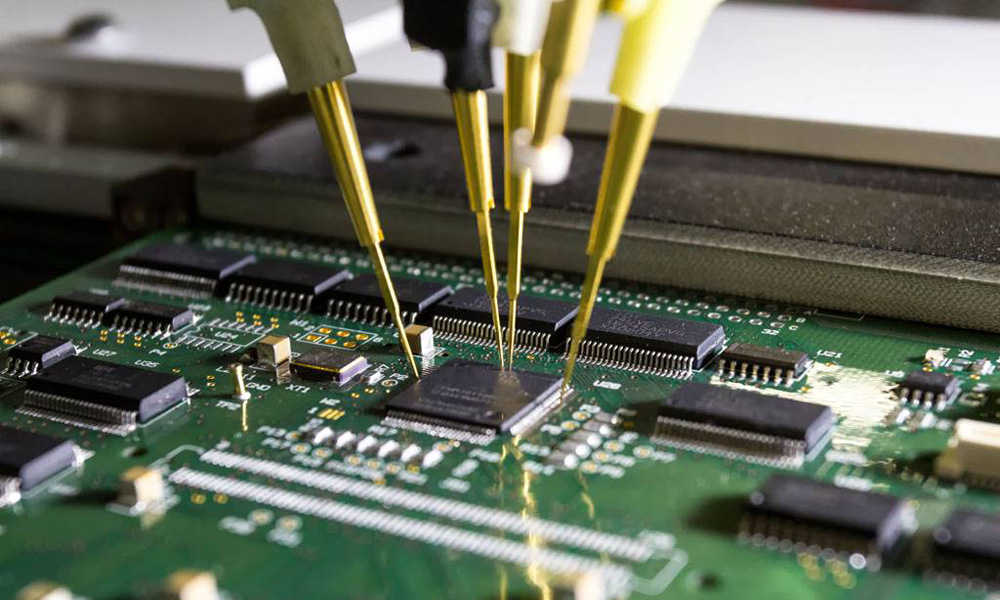

Inspection

To ensure the delivery of high-quality and dependable PCB assemblies, it is essential to perform inspections at various stages of the manufacturing and assembly process in order to eliminate surface defects. This involves assessing the design and manufacturing processes to determine their compliance with specified or general requirements, based on professional judgment.

Inspections for printed circuit boards can be customized to meet the specific requirements of each client. Timely and professional inspections play a crucial role in identifying defects prior to electrical testing and gathering data for Statistical Process Control (SPC).

Given the widespread use of Surface Mount Technology (SMT) in PCB assembly, inspections become even more vital due to the increased stress that SMT solder joints must endure compared to those using Plated-Through-Hole (PTH) technology. As SMT devices rely on the structural integrity of solder joints to remain securely attached to the board, conducting thorough inspections is paramount to ensuring the long-term electrical reliability of circuit boards.

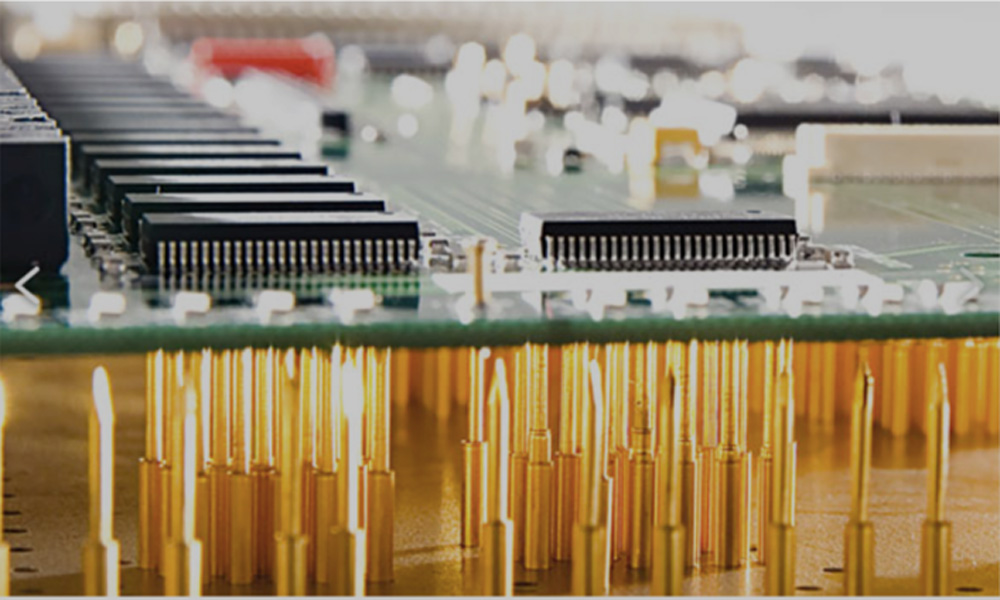

Test & Analysis

Testing and analysis are crucial processes during PCB assembly. Multiple tests are required to ensure the proper functioning of the fabricated board. It is a nightmare for any company to discover that a faulty board fails to power on.

To ensure the optimal performance of the final product, thorough testing is essential in electronic production. This is why the industry employs various testing methods and processes to ensure the correct fabrication and desired functionality and capacity of PCBs.

The following are some of the testing methods commonly used during PCB assembly:

- In-Circuit Testing

- Flying Probe Testing

- Automated Optical Inspection (AOI)

- Burn-In Testing

- X-Ray Inspection

- Functional Testing